Case Study

Methanex G3 Project, Louisiana, USA. $US1.3Bn

Methanex built a methanol plant integrating in-house expertise with licensor technology. It is one of the lowest-cost plants in the industry, has one of the lowest CO₂ emissions intensity profiles, and completed commissioning with industry-leading safety, cost, and schedule performance.

Methanex built a methanol plant integrating in-house expertise with licensor technology. It is one of the lowest-cost plants in the industry, has one of the lowest CO₂ emissions intensity profiles, and completed commissioning with industry-leading safety, cost, and schedule performance.

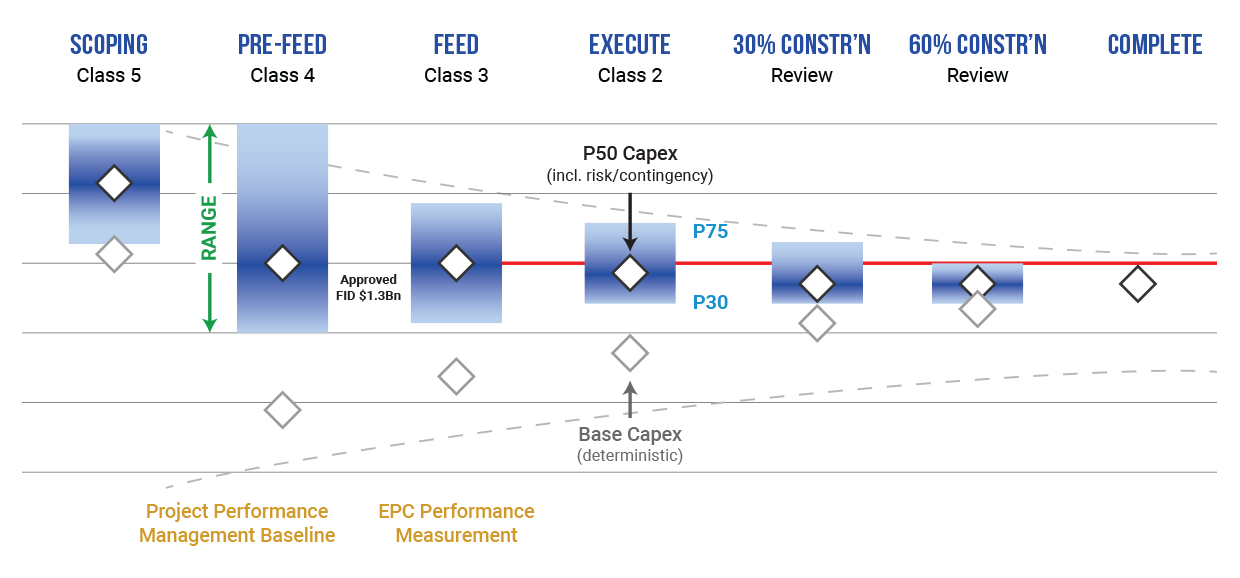

Success is underpinned by clarity and control. This required that the Methanex team clearly and explicitly define, at the outset, stakeholder expectations, scope, strategy, cost, schedule, and risk, to understand and effectively communicate what matters most. Risk evaluation is calibrated to project value.

A shared understanding of the key issues is paramount to identify what matters most and managing risk. This shared understanding was built not just through analysis, but through deliberate, ongoing conversations across the Owner, contractor, and service provider teams. Clear definition is crucial to quantify cost and time. This forms the basis for implementing effective control, consolidating team buy-in on what can impact key value drivers and ensuring intelligent use of cost, schedule and risk.

The quality and frequency of focussed conversations enabled the team to surface and address emerging risks, align strategies, and maintain stakeholder buy-in throughout development and execution.

Execution strategy is developed with insight into inherent uncertainties and risk tied to project value. The project progresses through development phases with informed management of cost, schedule and risk. A holistic understanding informs meaningful conversation when engaging service providers and contractors to establish fair value and control, retaining project value through execution. These conversations, as much about questions as answers, ensured the team could test and challenge the inherent limitations of cost and risk models—never mistaking analysis for certainty.

The G3 estimate was initially developed externally in the Scoping phase. Methanex brought the cost, schedule, and risk management in-house to drive value, deepen knowledge, and ensure the project aligns with safety, cost, and schedule expectations. In addition to managing the data models internally, the team cultivated conversations that adapted analytical outputs to real-world project requirements.

With the capital cost model in-house Methanex was better informed to improve project value, implement effective strategies, and establish management systems for control through execution. Bringing conversations ‘in-house’ around cost, risk, and schedule was as critical as any tool or process, ensuring that decision-making remained dynamic and adaptive.

Roctate led the conversation facilitation, cost and risk management processes as part of the Owner team, enabling the sophisticated dialogue that distinguished this project’s success. Our expertise supports Owner teams in bringing these critical processes in-house and plays a crucial role in maximizing project value.

“One of the learnings from the Project is that as the Owner, you need to own the estimating process yourself. While there are skills available in the marketplace, ownership is key to truly understanding what drives the cost. Primarily, these are scope and strategy.” — P. Bailey, VP Projects, Methanex

Own Your Project’s Success.

Maximize value by bringing cost, schedule, and risk control in-house. Understand what drives your project from the start and make informed decisions at every stage. Own not just the numbers, but the rhythm and substance of project conversations—where understanding is shared, and data models are wisely interpreted.